When Should You Use Copper Spray Lubricant?

Copper spray lubricant is essential in various industrial applications, particularly when dealing with high-temperature environments and heavy loads. As a B2B client, you might find it indispensable in automotive, manufacturing, and construction sectors. Its unique properties, such as excellent thermal conductivity and anti-seize capabilities, make it a go-to solution for preventing wear and tear on machinery. Therefore, understanding when to use copper spray lubricant can significantly enhance your equipment’s longevity and performance.

Can Coconut Oil Be Used as a Substitute for Copper Spray Lubricant?

While coconut oil is a versatile and natural lubricant, it falls short in high-temperature and high-pressure scenarios where copper spray lubricant excels. Coconut oil lacks the thermal stability and anti-seize properties that are crucial for industrial applications. Thus, substituting coconut oil for copper spray lubricant is not advisable, especially in demanding environments where the latter’s unique attributes are required.

Why Should You Pay Attention to the Supplier's Copper Powder Sourcing and Production Compliance?

Ensuring that your supplier adheres to stringent sourcing and production standards is vital. The quality of the copper powder used in the lubricant directly impacts its performance. Suppliers who maintain transparency about their sourcing and comply with industry regulations are more likely to provide a reliable product. This attention to detail not only guarantees the efficacy of the lubricant but also aligns with your company’s commitment to quality and sustainability.

How to Verify the Actual Copper Content and Extreme Temperature Performance of Copper Spray Lubricant?

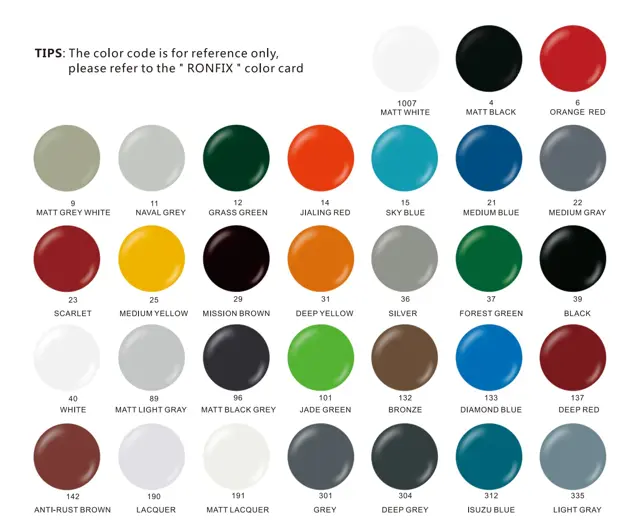

To ensure you are getting a high-quality product, it’s crucial to verify the actual copper content and its performance under extreme temperatures. Below is a table that outlines the key parameters to check:

| Parameter | Verification Method | Importance |

|---|

| Copper Content | Laboratory Analysis | Ensures product efficacy |

| Temperature Resistance | Thermal Cycling Tests | Confirms performance in extremes |

| Anti-Seize Properties | Friction and Wear Testing | Validates long-term protection |

By conducting these tests, you can be confident in the lubricant’s ability to meet your operational demands.

Can OEM Requirements Be Met? Comprehensive Support from Formula Adjustment to Packaging Customization

For businesses with specific needs, finding a supplier that offers OEM services is crucial. From adjusting the formula to meet unique performance criteria to customizing packaging for brand consistency, a supplier that provides comprehensive support can significantly streamline your operations. This level of customization ensures that the copper spray lubricant not only meets but exceeds your expectations, providing a tailored solution for your business.

Calculating Total Cost: Hidden Maintenance Fees and Equipment Protection Benefits

When evaluating the cost of copper spray lubricant, it’s essential to consider not just the purchase price but also the hidden maintenance fees and the benefits of equipment protection. While the initial cost might seem higher, the long-term savings from reduced maintenance and extended equipment life can be substantial. By protecting your machinery from wear and tear, copper spray lubricant can lower overall operational costs, making it a cost-effective choice in the long run.